Flat roof replacement is one of the most important maintenance investments commercial property owners can make. Flat roofs are durable and cost-effective, but over time, exposure to UV rays, standing water, and temperature fluctuations can cause significant wear. Knowing when replacement is necessary helps you protect your building, maintain tenant satisfaction, and avoid emergency repairs that disrupt operations.

- Cost efficiency: Replacing your roof at the right time prevents structural damage and reduces future maintenance costs.

- Safety and compliance: A new roof ensures your property meets modern building codes and fire ratings.

- Energy performance: Upgraded materials can lower utility bills and improve indoor comfort.

Understanding the Purpose of Flat Roof Systems

Flat roofs are common in commercial and industrial buildings due to their affordability and functionality. They provide easy access for HVAC systems, solar panels, and maintenance crews while offering strong structural support. However, unlike sloped roofs, flat systems must manage water drainage carefully to prevent leaks and deterioration.

When issues like membrane cracking, pooling water, or insulation failure arise, patching may only be a temporary solution. At a certain point, full flat roof replacement is the only way to restore integrity and ensure long-term performance.

Signs That Your Flat Roof Needs Replacement

Knowing when to replace a flat roof can save your business from costly downtime or interior damage. While repairs can address small issues, certain warning signs indicate that your system is nearing the end of its useful life.

Persistent Leaks or Moisture Damage

If you notice frequent leaks, water stains on ceilings, or soft spots in the roof deck, your flat roof may have widespread membrane failure.

- Recurring leaks: Indicate deeper structural issues, not just surface damage.

- Mold or odor: Suggests trapped moisture beneath the surface.

- Interior impact: Ongoing leaks can damage insulation, drywall, and electrical systems.

Visible Cracking or Bubbling

As roofs age, the protective membrane may blister, bubble, or crack due to trapped air or prolonged sun exposure.

- Surface blistering: Leads to seam separation and water infiltration.

- UV damage: Weakens material flexibility over time.

- Material fatigue: Indicates your membrane has exceeded its service life.

Ponding Water After Rainfall

Flat roofs are designed for minimal slope, but drainage issues can cause ponding that accelerates deterioration.

- Standing water: Promotes algae growth and surface erosion.

- Seam stress: Increases weight load and risks leaks at weak points.

- Drain failure: May require redesign during replacement for better flow.

Factors That Determine When Replacement Is Necessary

Commercial roof systems don’t all age at the same rate. The timing of replacement depends on several key variables that influence lifespan and performance.

Roof Age and Material Type

Different roofing materials have varying lifespans. EPDM, TPO, and PVC systems typically last between 20 and 30 years, while modified bitumen or built-up roofing may last slightly less depending on maintenance.

- EPDM rubber: Durable but may shrink or crack with age.

- TPO or PVC: Energy-efficient but vulnerable to seam failure over time.

- Built-up roofing: Excellent insulation but prone to blistering.

Maintenance and Repair History

A roof with consistent professional maintenance generally lasts longer than one with only reactive repairs.

- Documented upkeep: Helps extend warranty coverage.

- Neglected systems: Accelerate deterioration and reduce lifespan.

- Inspection frequency: Annual or semi-annual checks help predict replacement timing.

Structural and Drainage Conditions

If the underlying decking or drainage system is compromised, replacing the membrane alone won’t solve the problem.

- Deck integrity: Rotting or corroded decking must be repaired before installation.

- Slope correction: Improper slope leads to pooling and faster wear.

- Drain redesign: New systems can improve performance and reduce future issues.

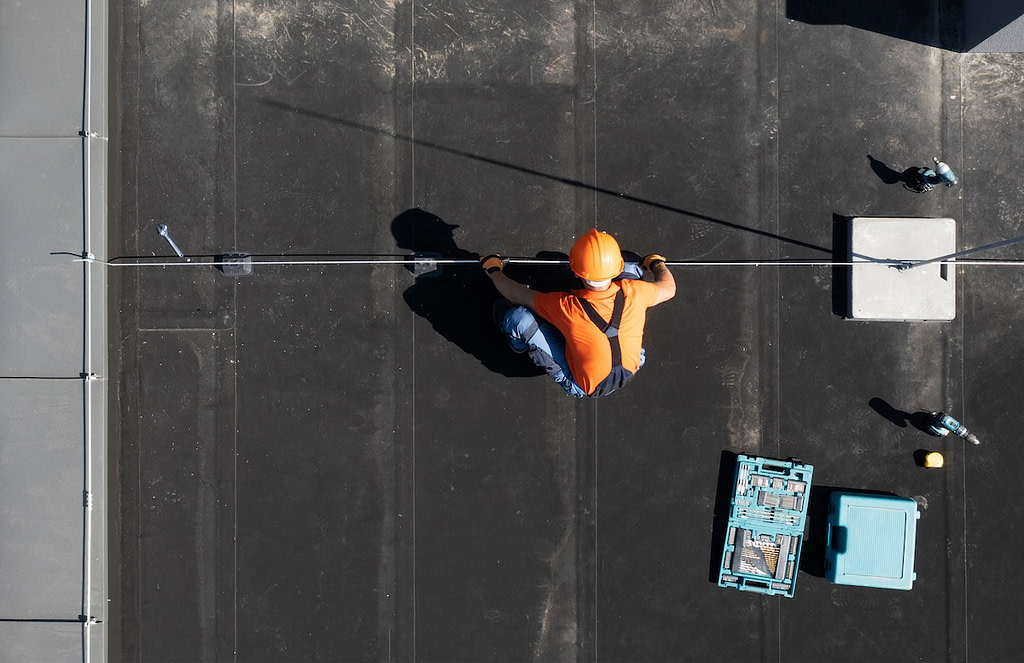

5 Key Steps in the Flat Roof Replacement Process

Flat roof replacement is a detailed process that ensures your new system performs efficiently and safely for decades. Professional installation guarantees proper materials, slope, and sealing to protect your building investment.

- Inspection and Assessment

Contractors begin with a full roof inspection, using infrared scans to detect trapped moisture and identify problem areas. They also evaluate decking condition, drainage, and insulation. - Removal of Existing Roofing

Old materials are stripped down to the decking. Damaged or wet insulation is replaced, and the surface is cleaned to create a smooth foundation. - Structural Repairs and Slope Adjustments

The team repairs any deck damage and adjusts slopes as needed to ensure water drains properly. New insulation may be added to improve energy efficiency. - Installation of New Roofing System

A new single-ply or built-up roofing membrane is installed. Edges, seams, and penetrations are sealed carefully to ensure a watertight barrier. - Final Inspection and Warranty Registration

After installation, technicians perform a comprehensive inspection and register any manufacturer warranties for long-term protection.

Replacement Options for Commercial Flat Roofs

Commercial property owners can choose from several roofing materials, each offering unique benefits depending on the building’s needs and climate.

EPDM Rubber Roofing

EPDM remains one of the most popular flat roofing systems due to its flexibility and proven durability.

- Longevity: Typically lasts 25–30 years with minimal maintenance.

- Weather resistance: Performs well in extreme temperature fluctuations.

- Cost-effective: Offers an excellent balance between durability and price.

TPO (Thermoplastic Polyolefin)

TPO is a reflective, energy-efficient option ideal for businesses in warmer climates or buildings seeking LEED certification.

- Energy savings: White surface reflects UV rays and lowers cooling costs.

- Seam strength: Heat-welded seams create superior leak protection.

- Eco-friendly: 100% recyclable material supports sustainability goals.

PVC (Polyvinyl Chloride)

PVC roofing combines flexibility with chemical resistance, making it ideal for restaurants, factories, or facilities with rooftop vents.

- Chemical tolerance: Resists grease and exhaust degradation.

- Puncture resistance: Durable against foot traffic and debris.

- Fire safety: Naturally flame-retardant for added building protection.

Modified Bitumen

Modified bitumen systems use asphalt layers reinforced with fiberglass or polyester for superior waterproofing.

- Proven reliability: Trusted in commercial roofing for decades.

- Multi-layer protection: Excellent resistance to punctures.

- Custom finishes: Can be applied with heat-welded seams or cold adhesives.

Cost Factors in Flat Roof Replacement

Pricing varies based on material type, roof size, and building complexity. Understanding these cost influences helps with budgeting and long-term planning.

Average Cost Range

- EPDM: $8–$12 per square foot installed.

- TPO: $9–$14 per square foot installed.

- PVC: $10–$16 per square foot installed.

- Modified Bitumen: $7–$11 per square foot installed.

Additional Cost Variables

- Insulation upgrades: Improved R-value materials increase energy efficiency.

- Tapered systems: Slope correction for better drainage adds labor and material costs.

- Accessibility: High-rise or congested sites require additional safety setup.

Investing in quality materials and professional installation ensures better performance and fewer repairs over the roof’s lifespan.

Maintenance Tips to Maximize Your Flat Roof Investment

A properly maintained flat roof can last decades and protect your property from costly damage.

Routine Inspections

- Twice-yearly checks: Inspect in spring and fall to catch seasonal wear.

- After storms: Look for punctures or seam separation caused by debris.

- Professional evaluations: Annual infrared scans detect hidden moisture.

Cleaning and Drainage Care

- Clear debris: Keep drains and scuppers free-flowing.

- Prevent ponding: Address pooling areas immediately.

- Inspect flashing: Tighten seals around HVAC units and skylights.

Preventive Repairs

- Seal cracks early: Small repairs prevent water infiltration.

- Recoat as needed: Protective coatings extend lifespan and reduce heat absorption.

- Maintain records: Track inspections and repairs for warranty coverage.

Protect Your Commercial Building With Young Construction’s Roofing Expertise

At Young Construction, we understand that a reliable roof is critical to your business operations. Our team specializes in commercial flat roof replacement, delivering durable systems that withstand harsh weather, minimize maintenance, and enhance building efficiency.

Why Property Owners Trust Young Construction

- Commercial expertise: Skilled in all major flat roofing systems, from EPDM to TPO.

- Customized solutions: We assess your building’s needs and recommend the most cost-effective option.

- Reliable performance: Every installation meets industry-leading safety and quality standards.

When it’s time to replace your flat roof, work with a contractor who understands the unique challenges of commercial roofing. Contact Young Construction today for a free inspection or quote and ensure your building is protected by craftsmanship and materials built to last.